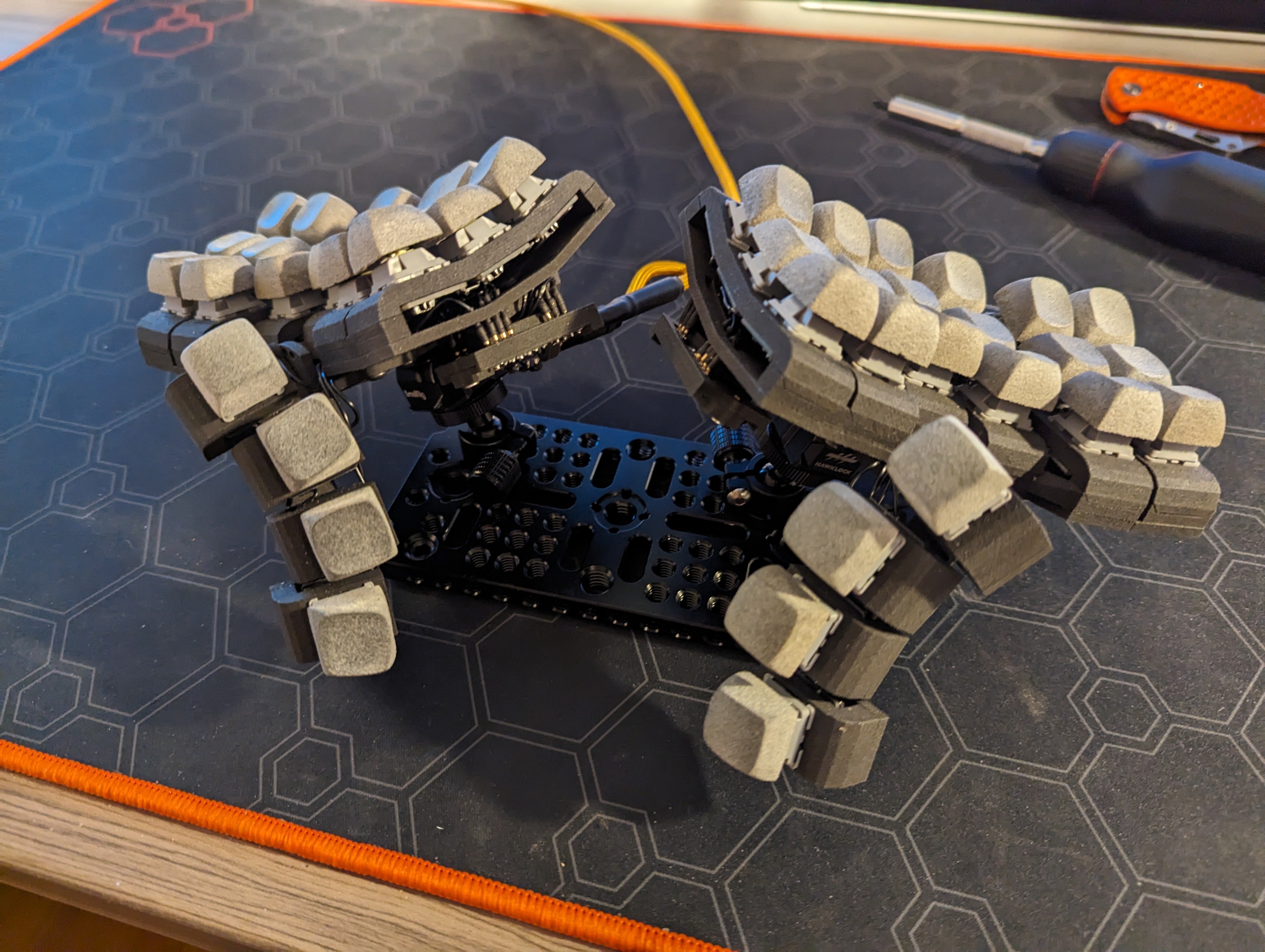

I decided to try out building myself the Explorer RxCT keyboard (posted on that other place shortly before the drama). Since this build is using rp2040 mc I've taken to calling it the Explorer Pi.

Of course I don't have my own 3D printer so I ended up using jlcpcb for the parts using SLS nylon. I'm quite pleased with how they came out.

Quite happy with the keyboard overall. I had being using choc switches for quite awhile so it took a little adjusting but not too bad and very comfortable to type on at this point.

Only thing I will probably change sooner or later is the thumb cluster. The modularity is great for narrowing down preferences but the construction means the keys are further spaced than I would prefer. I'm working on a two piece thumb cluster with tighter spacing at the cost of being a lot less customizable once I'm certain I've figured out what I want.

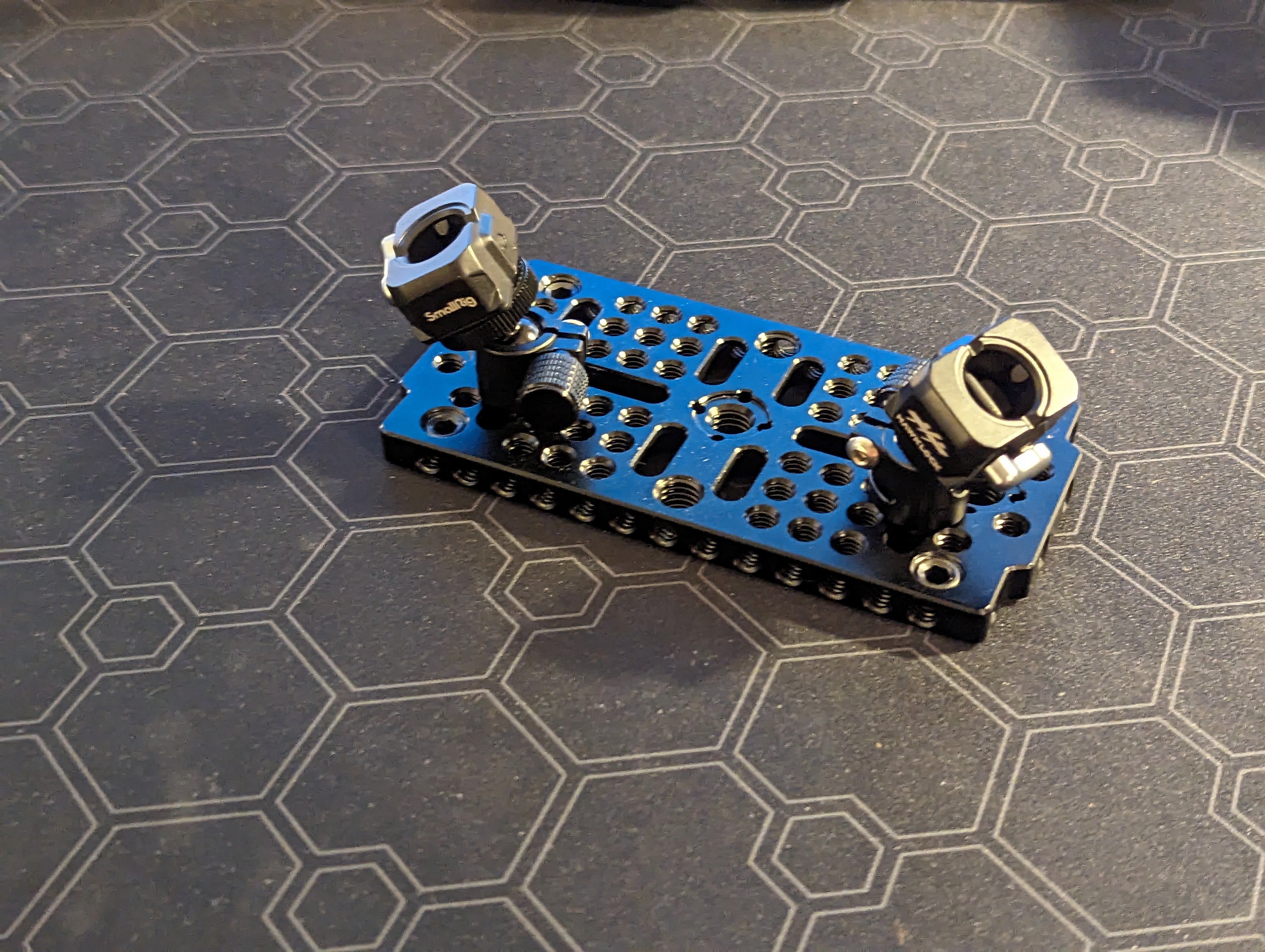

Loving the cheese plate for the base, I think there is something to be said for having a constant relative positioning between left and right hands. Only issue with it originally was that it would slide around a lot on the desk pad. I came up with a great solution:

Four 3/8" set screws secured in place with four more 1/4" set screws and this thing isn't sliding anywhere anymore. Also possible to use some longer set screws to add some additional Y axis tilting if desired.

Quick disconnect mounts for convince

Also worked out a mounting solution for on the go by mounting direct to laptop.

- Switches are Durock Sunflowers, with Spirit Slow II 45g springs

- Keycaps are 3D printed nylon DES from 3dkeycap.com

- Firmware on personal fork

- Personal Keymap

- Pull request for firmware into qmk official

- More photos here