this post was submitted on 01 Apr 2024

300 points (100.0% liked)

Technology

37719 readers

95 users here now

A nice place to discuss rumors, happenings, innovations, and challenges in the technology sphere. We also welcome discussions on the intersections of technology and society. If it’s technological news or discussion of technology, it probably belongs here.

Remember the overriding ethos on Beehaw: Be(e) Nice. Each user you encounter here is a person, and should be treated with kindness (even if they’re wrong, or use a Linux distro you don’t like). Personal attacks will not be tolerated.

Subcommunities on Beehaw:

This community's icon was made by Aaron Schneider, under the CC-BY-NC-SA 4.0 license.

founded 2 years ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

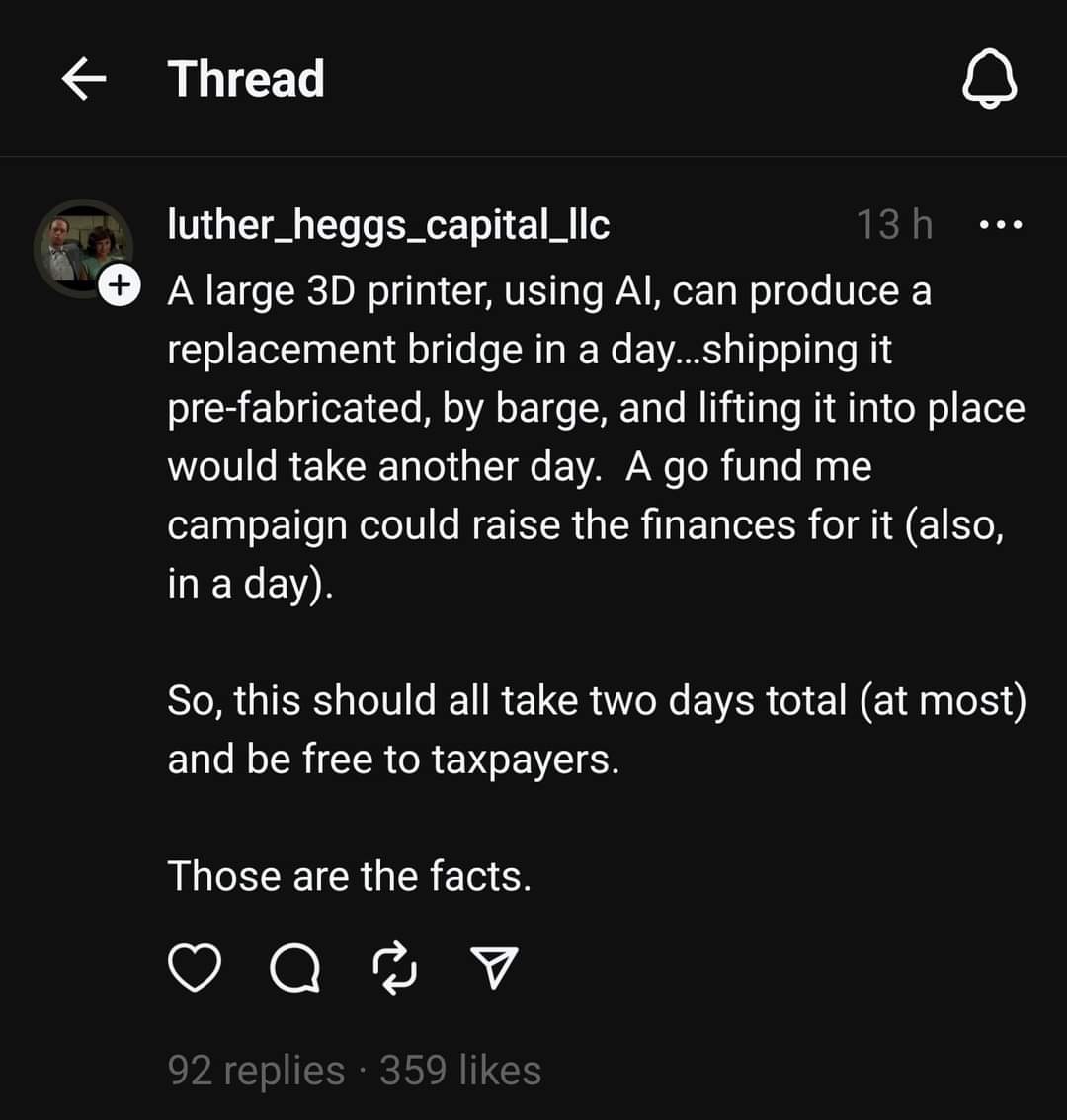

And is that huge 3D printer in the room with us now?

shakily points to an Etch-a-Sketch

Unfortunately it'll take 10 years to build the printer.

And even then, the filament needed at this scale will take another several years, and a few days for shipping.

Also, it doesn't do well in sunlight or high humidity for prolonged periods of time, so we'll need maybe 20 to 30 years to work out a solution for that problem.

I can only assume they're trying to talk about concrete 3D printing, but oh boy is that not ready for anything which needs strength.

How weak are we talking? All I've seen is the press releases from the companies that do it.

Yeah, but how much worse than normal unreinforced concrete? (Which is actually fine if you aren't worried about tension)

Oh it should be roughly equivalent. But really, what besides a slab can you build without worrying about tension?

Certain arches or domes, maybe a lining for a tunnel. A tower if it's not very windy. Really just all the stuff the Romans built, since that's what they were working with, and their volcanic ash-based cement was somewhat weaker than modern cement.

It would be pretty hard to print between rebar. You'd need a crazy multi-axis head, and at that point it's probably cheaper to just build a form. If they can achieve some significant strength with long fibers, which seems likely, you could spool that into the stream of concrete, but just concrete is already an actively researched problem. Printing one big form in foam or plastic and then filling it could be considered. The manual equivalent certainly makes a great building, especially in harsh climates where insulation is a concern.

Do you really think you could build a tower without tensile reinforcement? The hoop stress on the base of a cylindrical tower is no joke, especially when made from something as dense as concrete...

I will plead not a professional engineer on the one. The Tower of Pisa and it's less leaning cousins are thing, although Wikipedia informs me they were actually medieval and made of joined masonry rather than cast concrete, despite appearances. That's the main reason I brought it up.

It is right below your feet

Just cut up the model into a million smaller parts and post them on thingiverse so everyone on that site that already has a 3d printer can print one out and mail it to baltimore. EZ

To be fair, you don't need a very huge 3D printer for that, if you divide it into a lot of smaller parts which can be assembled later.

Idk, if we can already print steel though and whether we can make it structually sufficiently stable.

So our proposal is we prefab a bunch of metal pieces and assemble them on-site?

As opposed to our current method where we carve bridges out of a big block of metal?

Hahahaha absolutely. :D The difference is, that they come from a 3D printer and that's cool.

Well no, you put a conveyor belt in front of all the 3d printers, and when each part is done, it's dumped onto the conveyor belt, which leads all the pieces to an AI powered robot arm which assembles the bridge.

Yeah, I guess you could just run the conveyor belt and arm all the way to where the bridge needs to go.

All problems can be reduced to Factorio.

Where's the train? Why is there no train in the solution?

The bridge is science to unlock the train, of course.

Seriously, how we make bridges now with giant CNC machines is so inefficient! And all these people saying we should print lots of blocks to put together are totally forgetting about Legos, we all just need to donate our old Legos to Baltimore and let kids from anywhere come volunteer to build it. Free bridge and free child labour! Everyone wins

I find it difficult to believe that breaking down steel to be 3d printed into large structures for a bridge is faster or more energy efficient than casting the parts instead.

Steel beams get extruded and rolled, or... 3D printed with a large custom-shaped hot end! 🤯

https://youtu.be/lHTq-zLk-fw

We can indeed print steel with direct metal laser sintering. I think that the object needs heat treatment afterwards, though to be fair it is almost ten years since I properly read up on it and things have probably advanced since then

Maybe, we could just print off rectangular prism-shaped modules, around the right size to fit in a hand, and then assemble them on site. We could even make them out of ordinary clay and fire them for strength. I wonder why nobody has thought of that. /s

3D printing has it's place, but more conventional methods have theirs too. If you are counting on a lot of human labour anyway you might as well not reinvent the wheel.

OP said use AI, not humans... /s

You better start believing in huge 3D printers

…you’re in one!