3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or !functionalprint@fedia.io

There are CAD communities available at: !cad@lemmy.world or !freecad@lemmy.ml

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

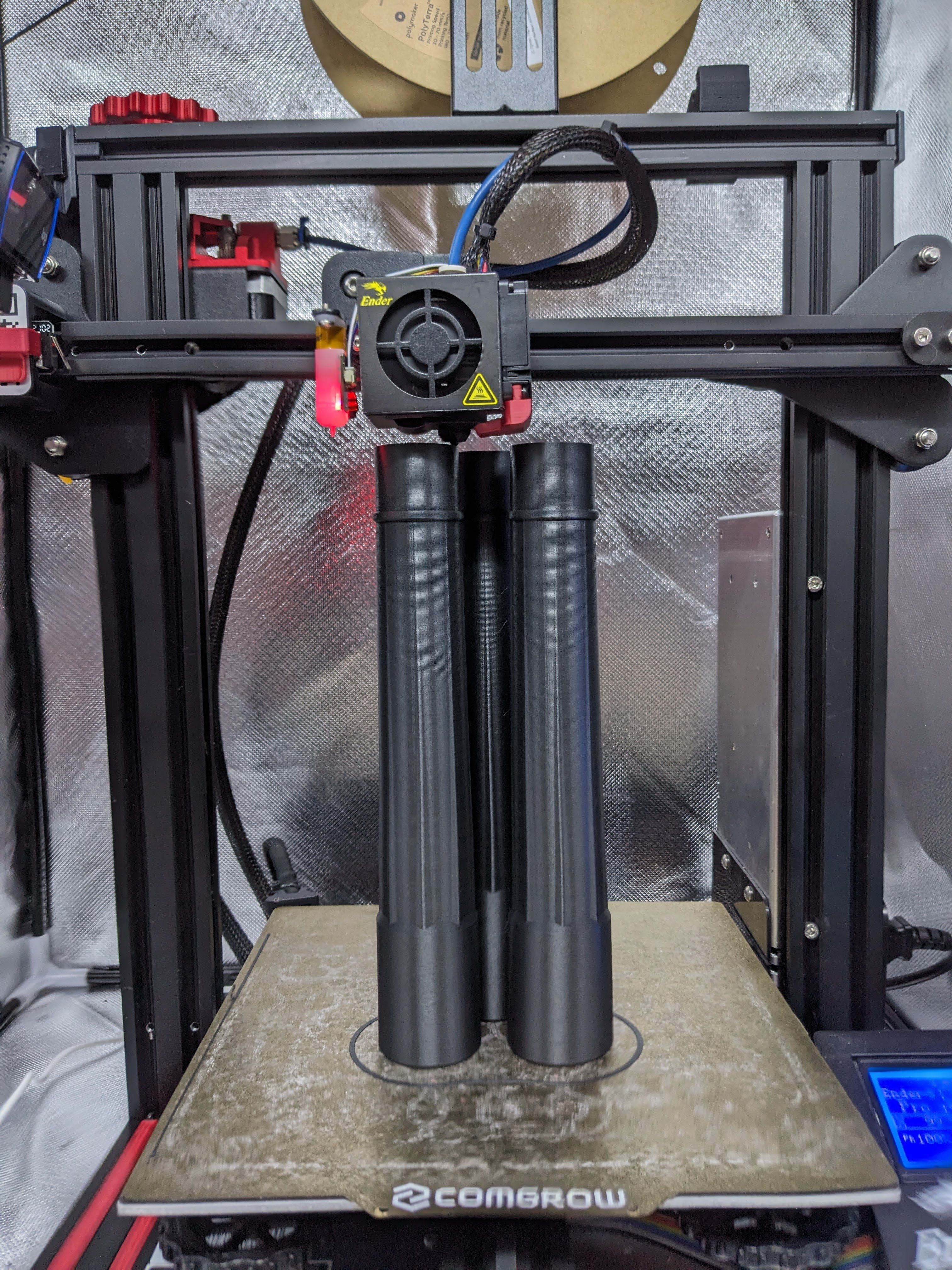

my brother in cad, it's a cylinder. a tube.

Well you've clearly never 3d modelled anything. Especially for a part that has to fit to existing parts, it takes far more time than just making a cylinder.

lololol

I started with 3dsr3 on dos bro. I design and model my own prints, ranging from input devices for vr to cosplay bits for the kiddos.

Yeah, I mean you're gonna have to bust out the calipers.... I don't mean to suggest there are one-step shortcuts, but at the end of the day, you have an exterior diameter and interior diameter to worry about so it fits other bits, and external details that may or may not be needed (flutes to strengthen the design for example). But for all that you'll spend way more time dialing in and printing tests to find the best orientation and support / adhesion / extrusion / infill etc...

but the modeling itself? an hour, a test print, fit test, adjustments, another test print (tests don't need to be all of the model btw, if you're just testing for fit to other parts!), then you should be on your way to a usable prototype. the cost of modelling should be the smallest sink in time cost.